Product Use - FAQ From Futaba: What servo do I need for my (insert application here)?

Please consult the manufacturer of your model. They have extensively tested the model and know how much torque, speed and what size servos are most appropriate for that application. Once they've given you those specifics, please visit our servo chart to select a servo which fits your model's specific needs and your budget.

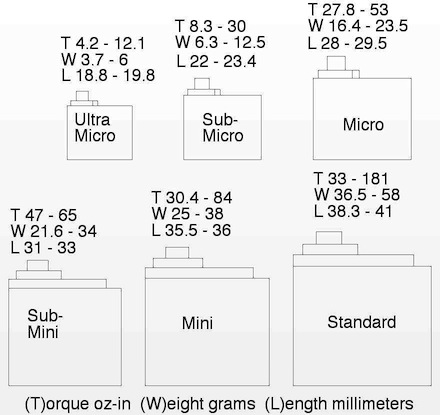

Hitec: Nano, Feather, Micro, Mini and Sport (includes various 'standard' servos)

Futaba: Micro, Mini, Standard

JR: Sub-Micro, Micro, Mini, Mid, Standard

Spektrum: Sub-Micro, Micro, Mini, Mid, Standard

Tactic: Micro, Mini, Standard

Heads Up Hobby: Sub Micro, Micro, Mini, Standard

Hobby King: Sub Micro, Micro, Mini, Park, Standard

A problem with the naming conventions:

Maxford USA recommends the following for their Antonov An-2; "Servos - 6 mini servos for electric power / 7 mini servos for glow power"

The precut servo slots in the fuselage tray are approximately 24mm in length.

Ken noted that he uses mostly Hitec servos. The Hitec 'Mini' servo is the HS-225 with a stated 54 oz-in of torque at 4.8V. It has a given case length of 32.26mm. Huh?

A servo list of was created in a spreadsheet for several manufactures. The list included, weight, external dimensions and the suppliers' stated torque.

The list is located in an Excel workbook at www.theampeer.org/ampeer/ampdec13/servo-data.xls

The list demonstrated that case length, without the tabs, was the most useful way to categorize servos.

The graphic shows that the servo trays in the An-2 are designed to accept Sub-Micro servos, not Mini servos.

The Chinese:

Many of the Chinese sourced RTF and Receiver Ready type models use what they call a 9g servo. The graphic illustrates that a 9g servo is a Sub-Micro and the torque ranges from 8.3 oz-in through 30 oz-in. This also illustrates why using the servo weight, like 9 grams, provides no real useful information to the user.

Nitro Planes carries a "brand" called Airfield. The warbirds come in different sizes and weights. They use 3S and 4S Li-Po cells and can weight up to about 90 ounces.

They use a servo similar to the Dynam DY-1006; Torque 22.2 oz-in, Weight 9g, Length 23mm. It is a Sub-Micro by Ken's definition.

The Airfield T-28 has a given weight of 88.2 oz and uses a 4S Li-Po.

Its torque in oz-in divided by RTF weight is 22.2 oz-in / 88.2 oz. = 25%

Servo Torque Calculators

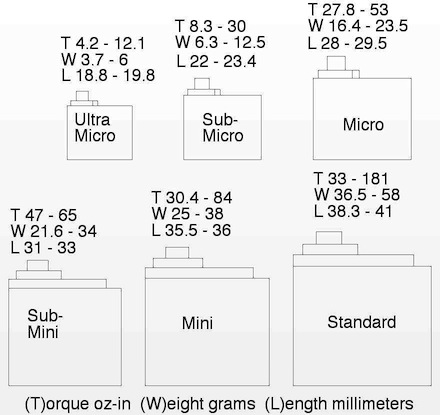

Chuck Gadd created an online calculator to suggest the required servo torque for various control surfaces.

A spreadsheet was created by Craig Tenny to calculate servo torque and it is similar to the Gadd online calculator.

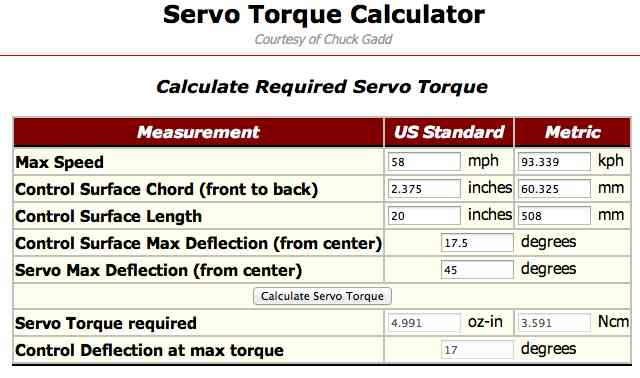

Alasdair Sutherland created and shared a nomograph in October of 1997. The nomograph and appeared in his column "aerodynamic forum" in August 1998 RC Model World. The nomograph is based on the work of Carl Risteen. Carl's article appeared in Model Airplane News in the Autumn of 1993.

A nomogram, also called a nomograph, is a graphical calculating device to allow the approximate computation of a value graphically.

The nomograph shows the required torque for a Maxford USA An-2.

Note: Ignore the light dashed lines on the screen capture from the CAD program. They are on the nomograph from some one else's previous calculation.

When using these types of calculators it is important to read and understand all of the caveats about this type of calculation.

Smaller servos have smaller gear diameters, thicknesses and control arms.

Some metal geared servos, use non-metal primary gears and other 'plastic' gears.

Chinese 'plastic' is prone to easy breakage.

Another way to derive a suggested Servo Torque in oz-in is to relate it to the plane's RTF Weight in ounces.

The Internet is full of misinformation on this topic.

I collected a great deal of data and it is available as an Excel workbook.

3D planes: (41 planes), Range 34% - 262%*, Ranged used: 34% - 105%, Average: 64%, Median: 59%

Example of an average plane.

The servo used on the elevator of a Carl Goldberg Extra 330 was a Hitec HS-5645MG with a stated 143 oz-in of torque.

The RTF weight was stated as 224 oz. 143 oz-in / 224 oz. = 0.638 or 64%

Glider/Sailplanes: (10 planes), Range 24% - 92%, Average: 56%, Median: 56%

Example: Great Planes Spirit 100 ARF, 62 oz., Futaba S148, 33 oz-in

33 oz-in / 62 oz. = 0.532 or 53%

Scale: (67 planes), Range 14% - 184%*, Range used: 14% - 103%, Average: 49%, Median: 45%

Example: League Models Extra 330 ARF, 252 oz., JR ST125MG, 125 oz-in

125 oz-in / 252 oz. = 0.496 or 50%

Sport: (53 planes), Range 23% - 326%*, Range used: 23% - 97%, Average: 60%, Median: 58%

Example: Great Planes Viper 500, sport/racing, 60.2 oz., Futaba S3101, 35 oz-in

35 oz-in / 60.2 oz. = 0.581 or 58%

There was not enough data collect on flying wings and EDFs to evaluate them.

Overall, it looks like 55% to 65% of RTF weight for servo torque in oz-in should work.

Ken found the scale aircraft data a bit of a surprise. Overall, the scale planes had the lowest average (45%) and median (49%).

The weight of the Maxford USA An-2 is about 98 oz. 98 * 0.45 = 44.1 oz-in of torque.

Lucien Miller, of Innov8tive Designs; 1 oz-in of servo torque per sq.in. of control surface.

The Maxford USA An-2 elevator has 47.5 sq.in. so that would be 47.5 oz-in of torqure required.

Lucien also cautioned that high speed aircraft need more torque and that low speed aircraft required less torque.

David Patrick from Canada: 1.5*A (Surface Area)*c(Average Surface Chord)*(V(mph)/100)2

An-2 elevator: 47.5 sq.in., Average Chord: 2.375 in.

Speed: 58 mph

Measuring Maximum Servo Torque

The idea for this servo torque tester came from an RC Groups thread named "Servo Torque Tester".

The photo shows a Micro Mark Digital Pull Meter attached to a servo arm with its hole one inch from the center of the servo screw hole. The servo is a Hitec HS-225 that is rated at 54 oz-in of torque.

It can supply a push or pull force of 54 ounces with a 1" lever.

A standard servo arm was attached providing a 9/16" or 0.5625" lever.

Inverse of 0.5625 = 1.777

55 oz-in * 1.777 = 97.8 oz. of force at 9/16"

Finally a servo arm/lever of 2" was used. The inverse of 2 = 0.5.

55 oz-in * 0.5 = 27.5 oz. of push or pull force.

As the servo arm length/lever is shortened, the available force goes up.

As the servo arm length is lengthened, the available force goes down.

A Hitec HS-225 with a servo arm connection 1/2" from fulcrum yields about 108 oz-in, while one 2" from fulcrum yields about 27 oz-in.

Some large models use a servo arm like this.

From the center of screw hole to farthest arm hole - 1.5645". The inverse = 0.639. Used with 333 oz-in Hitec Servo the torque would be 333 * 0.639 = 212.8 oz. of force.

This helps to explain why some of the torque divided by weight aircraft had very high percentages, 184% to 326%.

The Chinese, "Use What Ya Got and the Same Thing in Every Instance" us simple to produce and reproduce but just doesn't 'seem' right.

The online Calculator, Tenney Spreadsheet and Sutherland Nomograph take into consideration the surface area, surface deflection and speed but provide 'scary' low results.

But... see Keith Shaw's comments near the of this presentation article.

Using a suggested servo torque as a percentage of the RTF weight is easy to do but it doesn't take speed and surface area into account. It is also unclear as to what percentage to use.

Lucien Miller's suggestion of using 1 oz-in of servo torque per sq.in. of control surface is very easy to do but doesn't take speed into account.

David Patrick's formula is not that hard to do but it seems to add just a bit more torque to Lucien Miller's formula.

From Keith Shaw Regarding Servos Torque

Almost all my big electric scale planes use the Airtronics 102, rated at 50 oz-in. All of these use one aileron servo with bellcranks, so the servo only sees the NET load, plus a bit for linkage friction.

Bearcat, 15 lb., 21% (elevator servo had EMS ball bearing conversion)

CzechMate, 10 lb., 31% (elevator and aileron BB conversion)

Goon, 13 lb., 24% (elevator BB conversion)

Fokker D-8, 13 lb., 24% (elevator BB conversion)

Yak UT-1, 9 lb., 35% (elevator BB conversion)

Possibly the "scariest" was the first two or three setups in my 1/4-scale Great Lakes (80" span, about 2000 squares if I remember correctly), built in 1966. This was when it was in factory configuration (2 ailerons and inline 4 cylinder engine), before I did the red&white Hal Krier conversion with decreased dihedral, four ailerons and radial engine. Ailerons were via bellcrank, but the rudder and elevator were cable drive, with internal counterbalances to cancel out control surface mass. It originally flew with my homemade digital servos that, while huge, were only about 15 oz-in torque (my guess). Later it was flown with Kraft-10s, Kraft-12s, and even the little red EK servos, all with torques optimistically in the 15 oz-in range. The Great Lakes at that time weighed 12 lb., and was powered by a twin-plug Merco 61 or an early Webra 61 grey-head. I mostly just flew around or did touch&goes, but occasionally would do a mild loop, roll, stall turn or spin. So... early Great Lakes, #12, 8% !!!! :-O

When it was converted to the Krier version, it had Kraft-15s and later Kraft-20s, while the engines went from a OS Max 80 to a Quadra, Tartan, and finally a ST2500, while the weight peaked at 17 lb. BTW, the plane was fitted with full functional steel strip rigging. Those servos were about 50 oz-in, so the later Great Lakes, at 17 lb., for 18% was a little better. :-)

I would shudder to think the surface power/weight ratio on planes I flew with escapements, pulse rudder and Galloping Ghost!

Or my very first R/C plane in 1957 that weighed about 6 lb. and was laughingly "controlled" by a small rudder tab whose position was changed by two small relays. At best I would estimate an ounce of push on the rudder tab, with a 1" horn, so the equivalent of 1 oz/in of torque. A whopping 1% of the aircraft weight!!!!!!

Things to Keep in Mind When Selecting Servos

1. The servo arm length greatly affects the amount of force available.

2. Not all suppliers tell the truth about servo torque at a given voltage.

3. The voltage applied to the servo affects the available torque.

4. Servos really do vary in quality.

Ken's Thoughts for Now as This Is Still a Work in Progress

Keith's numbers make my An-2 servo choice, 30 oz-in servos, 98 oz. RTF wt., for servo torque being 30.6% or the RTF weight, seem reasonable.

Maybe the online calculator, spreadsheet and nomograph are not as far off as perceived, and then again, maybe not.