|

By Ken Myers Orginally appeared in the August 2007 Ampeer Modified for viewing on tablets and smart phones 08/10/2015 Newsletter of the Electric Flyers Only of Southeastern MI, USA EFO Site For a long time now, the correct timing to use for brushless outrunner motors has been a problem because of all of the conflicting information available in both the print media (magazines & instruction sheets packed with ESCs) and the Internet. Advanced timing was used on some brushed motors for "Sparkless Commutation". On high performance brushed motors, like the Astro Flight cobalt FAI motors, timing was advanced for an application where high amperages were to be drawn for most of the time when the motor was on, and partial throttle was not going to be used. F5b and LMR (limited motor run events) were two common aircraft applications, while car and boat drag racing were another. Advanced timing was used in these high amperage applications because as the power increased beyond a certain point, trailing edge "fire" appeared along the trailing edge of the brush and caused burning on the trailing edge of the commutator. This "fire" caused the positive brush to wear twice as fast as the negative brush. According to Bob Boucher in his Electric Motor Handbook Chapter 3 "Timing for Sparkless Commutation", "Over advancing motors is commonly done in racing motors where maximum power and maximum speed are all important. Over advancing a sport motor will cause excessive heating and failure if the motor is run at half throttle or less. Don't over advance the motor in a sport model where you intend to fly at half power much of the time."

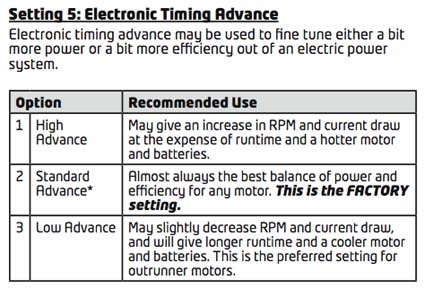

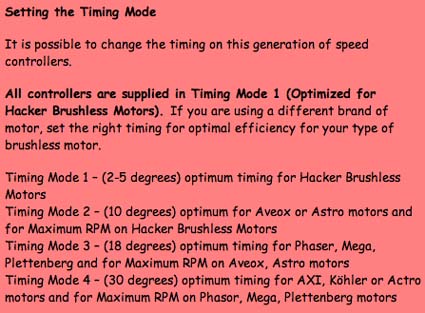

With brushless motors, all of the commutation, including the timing, is done in the electronic speed control (ESC) not the motor. The brushless ESC manufacturers SHOULD be the ones to know how to best use their products with different types of motors, but... Castle Creations appears to have no information on their Web site about timing, other than what is in the instruction manuals for each brushless controller. Here is what is in the manual today for the Phoenix-45. (It wasn't always this recommendation!).  Carefully read the last sentence in the Low Advance section. The FAQ (frequently asked questions) on the Castle Creation site contains no information about timing. It is actually hidden here under Special Note on Timing Advance. The following is my edited version of the paragraphs that Castle Creations has on the Web page noted above. "Special Note on Timing Advance:

What you'll find when you experiment with timing advance settings, is that going up or down from the normal setting will cause two reactions. With each step down from normal, your motor temp will go down and the top speed will go down about the same as dropping a tooth on the pinion. Going up, it's just the opposite - it's like adding a pinion tooth, but the motor temp will go up. (Obviously aimed at the car guys. KM) Over time with testing, we've found it's best to use a lower setting in order to keep motor temps in check, especially with very, very fast setups. Higher advance makes the motor run hotter, and the higher the Kv of the motor, the hotter it will get! Too high of an advance setting will give the same results as too much advance on a brushed motor - you will actually LOSE power and speed while the motor cooks itself!" It would be really nice if Castle Creations added a FAQ about the effects of timing on inner-runner and outrunner motors, high and low Kv, winds and types of motors. Here is a link to some timing information for a Hacker ESC.  Note that the Timing Mode 1 is most likely referring to the B Series inner runner Hacker brushless. You can see they are recommending 30-degrees on outrunners. And still another link to the Welgard 65-amp instructions in .pdf format.  A quick review is in order;

Searching the Web will provide even more confusing information. Many times I've seen that outrunners should be timed with 30-deg advance, and equally as many times a 15-deg advance.

I still had my BP/TowerPro 3520-7 on the test stand, along with the Welgard 65-amp (now discontinued and replaced by the BP 60A Brushless ESC for only $24.95!). On Monday, June 25, 2007 I ran a series of tests to answer the following questions.

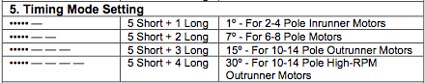

The timings available on the Welgard 65A in degrees are 1/7/15/30. The temperature through the 5-hour testing period ranged from 84F to 90F, with the barometric pressure about 30.15 in. and humidity in the mid-40% range. The testing was done just inside of my garage at the garage door opening facing north, while the rear entry door of the garage was left open for some airflow. The battery for the prop testing was my 6S1P M1 A123 LiFePO4 pack from bigerc.com. It was used at ambient temperature and recharged after each round of testing, as described in the August 2007 Ampeer. Io, the no load current, has always been considered a constant, but is it?

4S1P Skyshark 4000mAh 10C Li-Po

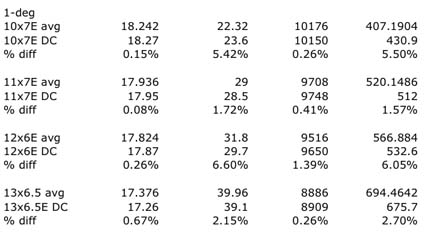

Io goes up with the timing advancement. This was NOT an unexpected result, as it also does with brushed motors when the timing is advanced! Conclusion, Io cannot be given for a brushless outrunner as part of the "motor" data as it is dependent on the ESC design and manufacturing and how the end user sets the timing. Please note that the real system power out is a very "iffy" calculation without a dyno. The number indicated here for system Power Out (Pout) is based on my best guess using my spreadsheet data and some prop data. Please don't assume that power system is as efficient as it appears here, but since the same type of calculation was used to figure the system Pout, the relative numbers will remain pretty much the same APC 10x7E

APC 11x7E

APC 12x6E

APC 13x6.5E

If Kv were a constant, then the highest voltage in with the lowest amp draw should produce the highest RPM, but actually, when the timing is advanced, the highest advance produces the highest RPM with the lowest input voltage; therefore the Kv must be relative and not absolute. Relative Kv is changing with the timing. Therefore, the Kv number given by a motor manufacture is a relative number and once again will be determined by the specific ESC and timing chosen by the end user. What happens to the Rm (apparent motor resistance)? Unlike a brushed motor, the brushless motor will not run without the ESC to do the commutation. Thus, the ESC is actually a part of the motor and any Rm number given by a motor manufacture is pretty useless as it is only one part of the actual brushless motor system. While the motor Kv can be derived using the drill press method, once the ESC is factored into the motor equation, everything changes. One way to find out how the Rm, which I now like to call the motor/ESC relative resistance (Rme) is affected by the relative Kv is to do a quick and dirty relative Kv calculation. Using the no load data from above, here are the quick and dirty relative Kv calculations. Note that these numbers are all slightly higher than the real Kv, but close enough for a comparison.

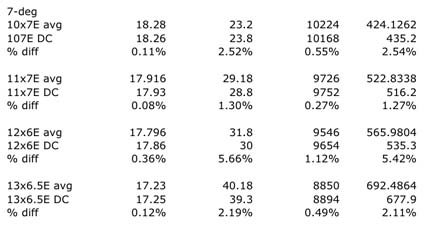

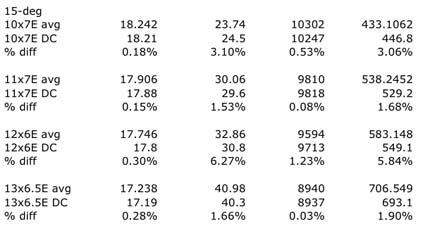

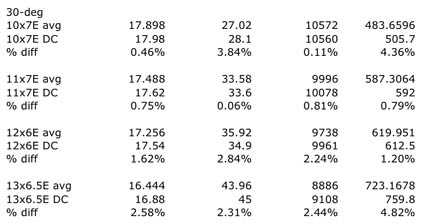

Using the relative Kv the output volts can be estimated, and that voltage can be used to calculate the relative Rme using the voltage drop and amp draw for the various prop runs. When this is done, (I'm not showing it here, but I'll be happy to provide my spreadsheet to anyone interested) it can be seen that the relative Rme goes down as the amps go up within any timing setting and that the relative Rme also goes down as the timing is advanced. Since the simple and most used way to predicted brushed motor performance is based on the Io, Kv and Rm being constant, it is easy to see why those constants fail when predicting outrunner brushless performance. I have been advocating the use of Drive Calculator for predicting motor/battery/prop performance, because it is NOT based on Io, Kv and Rm being constants! Here is why I believe in the performance predictions of Drive Calculator. The following shows my measured data compared to the information output by Drive Calculator. Remember that Drive Calculator has to take into account all of the changing "constants" of the motor and ESC, as well as what is going on with the power supply, in this instance a 6S1P M1 pack and manipulate the prop data and arrive at a prediction. You be the judge. (avg is my actual measured average and DC indicates the Drive Calculator Prediction. The numbers are presented in this order; volts in, amps, RPM and Watts In)

Low timing should provide the power and efficiency I want when I use this motor and help keep all parts of the power system quite "happy." Link to the FREE Drive Calculator program for the Windows, Mac and Linux operating systems. To Reach Ken Myers, you can land mail to the address at the top of the page. My E-mail address is: KMyersEFO@theampeer.org |