by Roger Jaffe Model Builder - June 1994 Beginning with the May 1993 issue I did a three-part column discussing my method of predicting the performance of prospective electric models. I received quite a bit of mail from readers about my theories and formulas. Just about everyone who wrote either applied my formulas to their models or shared their own flight prediction systems, and I'd like to pass some of their ideas along to you. Let's review my method of determining flight performance. First, figure the wing loading in ounces per square foot. Next, compute the power-to-weight ratio by dividing the input power (watts in, figured by multiplying the battery voltage by the current draw) by the ready-to-fly weight (ounces). Finally, find the Aircraft Performance Ratio (APR) by dividing the power-to-weight ratio by the wing loading. The APR will indicate the model's expected flight performance according to the ranges listed below:

WING CUBE LOADING Using these parameters to evaluate performance has worked well for me, but fellow Model Builder columnist Francis Reynolds wrote with some suggestions on how to make these indicators even better. He notes that characterizing an aircraft's performance based on wing loading leads to inconsistencies among models of different sizes.

IMPORTANT NOTE: December 2021 - The formula in the preceding paragraph is NOT the same formula as in the Francis Reynolds article.

Reynold's formula: wing cube loading (WCL)= weight in ounces (oz.) divided by (/) wing area in feet raised (^) to the 1.5 power

Jaffe's formula from above: Wing Cube Loading (WCL) = wing loading in ounces per square foot (oz./sq.ft.) divided by (/) the square root of the wing area (sq.ft.) raised (^) to the 0.5 (Raising to the 0.5 is another way to calculate the square root of a number and yields the same result as using the square root key on a calculator.)

Example for the full size Cub Example below:

Typical Wing Loading: weight in ounces (oz.) divided by (/) wing area in square feet (sq.ft.) - 17,600 oz. / 178 sq.ft. = 98.876404 oz./sq.ft.

Reynolds: 17,600 oz. / 178 sq.ft.^1.5 = 17,600 / 2374.8162 = 7.4110999

Jaffe: 98.876404 oz./sq.ft. / 178 sq.ft. ^ 0.5 = 98.876404 / 13.341664 = 7.4110999

Keep in mind that either formula yields the same result! Francis claims that every J-3 Cub from a very small model to a full-size one will have about the same wing cube loading. Let's test him!

IMPORTANT NOTE: February 2018 - There should be no units attached to the Wing Cube Loading (WCL) value. See my Personal Comment, added in February 2018, to Francis Reynolds article. It is easy to locate my comment as it is also in a blue font. As you continue reading this article, ignore any reference to ounces per cubic foot. My ElectriCub model weighs 50 ounces and the wing area is 429 square inches. Plugging everything into the equation gives a WCL of 9.72 ounces per cubic foot. The Goldberg Anniversary Edition Cub (gas power) has a wing area of 744 squares and a ready-to-fly weight of 120 ounces; its wing cube loading is 10.2 ounces per cubic foot.

The difference in WCL numbers is insignificant compared to the difference in wing loading numbers, particularly between the two models and the full-size plane. As you can see, Francis has normalized the size difference between planes of the same type.

Type of Aircraft Wing Cube Loading

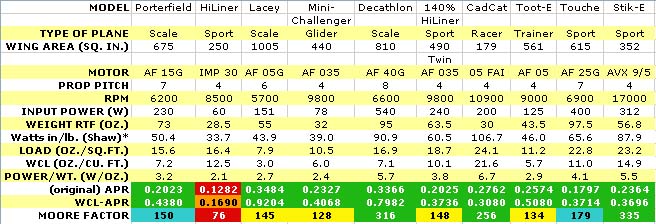

Computing the WCL parameters for various models as shown in Figure 1, I have to agree with Francis in his analysis of wing cube loading because each plane's type and its WCL category are consistent. The APRs of many of the planes gave an indication of performance but were not accurate in judging the degree of success or failure. So, let's take this WCL thing a step further and compute a new Aircraft Performance Ratio using the WCL parameter instead of the wing loading. I'll call this the WCL-APR, found by dividing the power-to-weight ratio by the WCL (not the wing loading as before). The WCL-APR fixes a couple of inconsistencies with my previous numbers. (For comparison, the old APR numbers are also shown in Figure 1.) For instance, my 1/4-scale Lacey was very powerful and would literally jump off the ground, yet the APR was only 0.348. The WCL-APR parameter is much higher, 0.920, which agrees more with the actual flying characteristics. Remember that this plane has a very low aspect ratio and lots of wing area. The WCL parameter appears to take this into account. The Toot-E was also very powerful for its size. Its WCL-APR is now 0.508 (from 0.257) and agrees with its actual flying performance. The HiLiner had an APR of 0.128 but a WCL-APR of 0.169, a small increase. However, the performance is still marginal-changing my method of judging performance hasn't fixed that! Obviously the performance characteristic ranges need to be adjusted. Looking at all of my data (including data from many planes that are not listed here), I think the correct ranges should be like this: WCL-APR Performance

I like the WCL parameter; using the WCL and the WCL-APR parameters for my electric aircraft analysis is more accurate than the regular wing loading parameter because it does what Francis says it's supposed to, normalize the size variations of aircraft. Rod Moore of Canoga Park, California and I have carried on a lively debate about this subject since my last set of articles. His aircraft performance number uses a different set of parameters that I want to share with you.

Figure 1 lists Rod's performance factor for each of the planes, as you can see, it's right on the money. This is another electric aircraft performance factor that works very well in judging flight performance. Renowned electric flight master Keith Shaw has his own method of evaluating aircraft performance; it was published in the July 1987 issue of Model Builder. It is more of a design tool, since it's used in the early stage of designing and analyzing an electric model. It's too long to fully restate here, but if you want the full details, look up the issue or send me an SASE and I'll send you a copy. Summarizing, here's how he does it:

Now that we have three methods from which to choose, let's take a look at the similarities and differences between them. With Rod's and Keith's methods you need to know the rpm and the prop pitch for the kind of motor you want to use. This isn't so hard to do, particularly if you've been reading the electric columns for a few months. Not a month goes by that there isn't some motor and prop speed data. I've compiled a list of motor and propeller data I've saved over the years it's yours for an SASE. Of course, if you really don't have any idea about the speed and power of your motor, you can always test the system on your workbench.

AND ROD MOORE PERFORMANCE PARAMETERS

COMPUTER PROGRAM UPDATE My computer program has been updated and a new version should be available by the time this column is published. It now includes the WCL and WCL-APR computations and Rod Moore's performance predictor. For those who have an older version, the update is available by sending $2.50 (to pay for photocopying the new operating manual, and postage) and your original diskette to me. If you don't have the old version and would like to buy the new version, send me $15 and I'll mail it out to you along with an updated manual. | ||||||||||||||||||||||||||||||||||