|

Flying High With Electric Power!

The Ampeer ON-LINE!

Fly the Future - Fly Electric! |

|---|

Site Table of Contents

| President: | Vice-President: | Secretary-Treasurer: |

| Ken Myers | Richard Utkan | Rick Sawicki |

| 1911 Bradshaw Ct. | 240 Cabinet | 5089 Ledgewood Ct. W. |

| Commerce Twp., MI 48390 | Milford, MI 48381 | Commerce Twp., MI 48382 |

| (248) 669-8124 | (248) 685-1705 | (2480 685-7056 |

| ||

| Board of Directors: | Board of Directors: | Ampeer Editor |

| David Stacer | Arthur Deane | Ken Myers |

| 16575 Brooklane Blvd. | 21690 Bedford Dr. | 1911 Bradshaw Ct. |

| Northville, MI 48167 | Northville, MI 48167 | Commerce Twp., MI 48390 |

| (248) 924-2324 | (248) 348-2058 | (248) 669-8124 |

| The Next Meeting: Date: Saturday, June 1 Time: 10 a.m.

Place: Midwest RC Society 7 Mile Rd. Flying Field | ||

| More on Selecting the Capacity of a Li-Po for a Given Motor, Ken Myers looks more into this topic. | Review: Eagle Tree eLogger V4 Ken Myers reviews this useful device. |

| Upcoming Keith Shaw Birthday Party Electric Fly-in 2013 info and map | Upcoming Lake Orion E-Fly-In Pete Foss provides information on the upcoming Skymasters E-fly-in in June. |

| More on "Can the Data From the Castle Creations/ Phoenix ICE 50 (8S) Be Used to Collect Inputs for Drive Calculator?, Ken shares more thoughts on this topic. | Announcing the 29th Annual Mid-America Electric Flies, links to the Flyer and map and hotel info for the 2013 Mid-Am. |

"In the May 2013 Ampeer I gave some formulas for calculating the capacity for a Li-Po when used with a given motor in the article "Selecting a Li-Poly Battery for a Given Motor". For a "quick and dirty" method, I gave the following formula:

I did not explain where this formula came from. Several years ago I ran across this formula on RC Groups for finding the amp draw for a given motor based on its weight in grams. I'm sorry, I cannot credit the source, as I didn't note it at the time.

I used a 60g motor in the previous example.

The formula did not prove too helpful for motor amps. I usually came up with the maximum continuous amps for the highest number of winds in a series of motors. The Cobra C-2213 series was used last month. The highest number of winds, lowest Kv is the Cobra C-2213/26 (950Kv) with a recommended maximum continuous amp draw of 14. That is very close to the 60g example from above. But... The Cobra C-2213/12 with a Kv of 2000 has the fewest number of winds and a recommended maximum continuous amp draw of 30. I played with the formula for a long time and then discarded it as useful for yielding a recommended motor amp draw. While 'playing with it', I also realized that the formula can be rewritten as:

When Phil Alvirez asked about battery sizing, I went, "Ah ha!" For battery capacity sizing, the formula can work if divided by the C rate of 10, which gives a decent flight time. To allow for motors in the same series with a higher amp draw, I suggested a manufacture/supplier 20C rating or higher for the cells. For a 60g motor I showed the following:

A pack with a 20C or higher rating would cover all of the acceptable amp draws noted for the Cobra C-2213 series. A 1.55Ah battery at a 20C discharge rate is 31 amps." The Cobra C-2213/12 is rated for 30 amps continuous. I also provided information and formulas on two other series and weights of motors to show that, for a rule of thumb, this works reasonably well. Without a lot of information being supplied by MOST manufacturers and suppliers about their motors, a simpler method is to just use what they have given. Hobby King supplies a 61g outrunner, the Turnigy L2215J-900. Hobby King notes, "Max Current: 18A" and states, "ESC: 20A". Using Hobby Kings' 18A maximum current, then a 1.8Ah or 1800mAh capacity Li-Po should be acceptable. Yep, just divide the given amps by a 10C rate for the Ah. Remember that Ah * 1000 equals the mAh. In this case a manufacturer/supplier 15C rating or higher Li-Po could be used. The bit more complicated formula used for the 60g motor shows a 1550mAh capacity at 20C or higher, but by just dividing the supplier's amp rating by a C rate of 10 yields a decent capacity and duration without excessive weight. Hobby King notes, "Voltage: 11.1v (3s)", so the weight of a 3S 1800mAh Li-Po can be estimated as 1800mAh / 37 * 3 cells = 145.9g Why 37? I honestly don't know, but it works reasonably well. A Turnigy 1800mAh 3S 20C Li-Po Pack weighs 153g. That is not a lot heavier than a 3S 1550mAh calculated and then found in last month's issue.

Hobby King also noted a 20-amp ESC. When the 80% rule is applied to the 20-amp ESC the result is 16 amps. Dividing 16 amps by a 10C rate is 1.6Ah or 1600mAh. A ZIPPY Flightmax 3S 1600mAh 20C Li-Po weighs 122g. I'll let you do the math using the weight formula to see how the formula compares to the stated weight by Hobby King. Any of the four methods in this issue, and the May 2013 issue of the Ampeer, should give a good idea of what capacity to use, and the manufacturer or supplier 'usually' supplies a recommended number of cells. Review: Eagle Tree eLogger V4

My favorite bench test data logging 'tool', for capturing data for input into Drive Calculator is the Hyperion Emeter 2 with its remote data unit (RDU). Also, the RDU can be hooked up onboard an aircraft and log amps, volts, rpm and even more types of data during a flight. While poking around online in March 2013, I noticed that the Emeter 2 with the RDU was becoming hard to find. All E RC showed it on backorder for over three months. It also showed a price drop. I checked RC Dude and found all Emeter 2 items in-stock, but at reduced prices. Overall, Hyperion products are becoming harder to find. Many times a price drop indicates that an item is being discontinued. If that is the case, it is too bad, as the Emeter 2 and RDU is a superior power system data collection system! I want to make it ABSOLUTELY CLEAR that I have no knowledge that the Emeter 2 is going to be discontinued. I am just musing aloud.

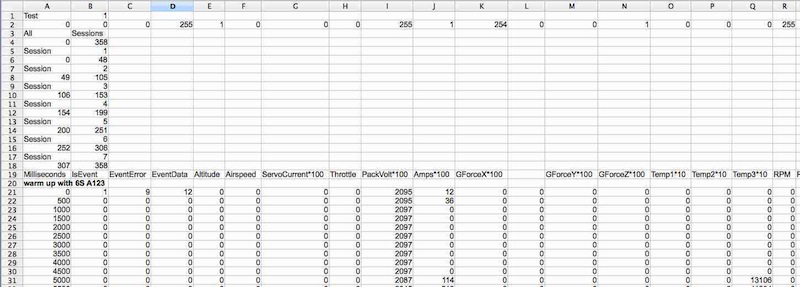

My Eagle Tree eLogger V4 With that information in the back of my mind, I decided to give another brand of data logger/recorder a try. On February 11, 2013, I placed an order with Tower Hobbies for the Eagle Tree Systems eLogger V4 100A w/Wire Leads ($58.99), Eagle Tree Systems Brushless Electric Motor rpm Sensor ($13.79) and the Eagle Tree Systems Power Panel LCD Display ($28.19). With $15 off and free shipping, the units arrived at my door for $85.97. Shortly after ordering, I downloaded the current manuals onto my Mac, in .pdf format, for the eLogger V4, Brushless RPM Sensor and the PowerPanel LCD display expander from the Eagle Tree Systems, LLCTM Web site. I read through the manuals to familiarize myself with the items. I also downloaded the latest software onto my Toshiba Netbook, which runs the Windows XP Home Edition operating system. I found that I could not 'preview' the software as the eLogger, or another of Eagle Tree's products, must be connected to the Windows computer via a USC link to activate the software for the first time. After the initial set-up, the software is accessible and previous saved files may be viewed. When the items arrived, I inserted the CD that was packaged with the eLogger V4 into the Mac to see what was on the CD. The Netbook has no CD-Rom capability. The CD contains the Windows program and support files and the manuals for all of the Eagle Tree products. I compared the manuals for the eLogger V4, brushless rpm Sensor and LCD on the CD to the ones I'd previously downloaded. I found the ones on the CD to be 'older' versions. (The second unit came with a newer version of the CD included.) I plugged the eLogger V4 into the Netbook with the provided USB cable and opened the current software version (10.44). The setup was completed. The eLogger V4 and PowerPanel LCD Expander are made in Taiwan and the Brushless RPM Sensor in China. The eLogger V4 is covered with a somewhat brittle, clear shrink wrap. It was shrunk tightly around the pins where the brushless rpm sensor needed to be inserted. Before going to the basement to get a razor blade to cut the shrink wrap away from the pins, I played with the shrink wrap with my finger. A section of the plastic shrink wrap split right off where I wanted it to. (Also see my notes about this shrink wrap regarding the seconded eLogger V4 I received.) The brushless rpm Sensor and supplied throttle "Y" connector were connected to their appropriate pins with a typical three pin JR "servo" type connector. Correct polarity is noted in the manual and on the eLogger V4 label. Next, unfortunately, I got the horse before the cart and assumed that the eLogger V4 would work correctly right "out of the box". My original plan was to compare the eLogger captured data to that captured by the Emeter 2 and a Castle Creations Ice 50 ESC. A no load test was run on the bench using a previously setup O.S. Motor OMA-5010-810 motor. The eLogger was plugged into the Netbook and the Eagle Tree software used to download the data. The data captured by the eLogger V4 is saved in final draft document (FDR) format. The eLogger's Data File is compatible with ExcelTM spreadsheet software, and other spreadsheet products supporting space delimited data files. I prefer to look at data on a spreadsheet, rather than the provided software. The eLogger file was moved to the Mac and the Open Office spreadsheet used to open it. The file opened okay, but the headings had shifted one place to the right at column L. This caused the RPM data to be displayed in the column labeled Temp 3*10. The data from the Emeter 2 and eLogger V4 were combined on a spreadsheet for comparison. Unfortunately, the data for the no load test was off quite a bit when compared to the Emeter 2. The eLogger V4 showed higher voltage and amperage and lower RPM than the Emeter 2. Which was correct?  Once the data discrepancy was discovered, I decided to do much better comparison testing. I checked the calibration of the Emeter 2 using my Radio Shack Digital Multimeter Cat. No. 22-168A. I tried to calibrate the eLogger and was unsuccessful. Version 1.6 of the eLogger V4 manual states, "The eLogger's voltage and amperage measurement system is factory calibrated. If you'd prefer that the eLogger's readings match the readings of another instrument you are accustomed to using, the calibration feature is included. However, if your eLogger is reading inaccurately, please see the troubleshooting section below before recalibrating." I followed the trouble shooting procedure to re-zero the current, "If the current being logged by the eLogger appears to be incorrect, connect a battery pack to the eLogger, and connect the eLogger to USB. Then, click "Calibration, Rezero Current Sensors" to rezero your sensor. Make sure that no ESC or other load is connected to the eLogger during this step! Note that this calibration step is done at the factory before shipping, but it may be possible for slight sensor drift to occur after the eLogger has been in operation for some time." Obviously it had drifted. After three very frustrating days of trying to calibrate the unit, I opened a thread in Eagle Tree's Vendor area on RC Groups on March 7, 2013.

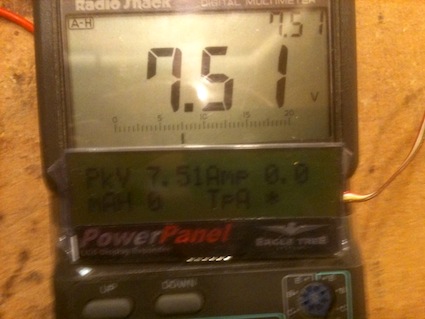

After exchanging information with RC Groups billpa (Bill Pauley), Eagle Tree said that they would replace the eLogger V4. A support ticket was opened on March 8 and on March 9, a Friday, I received an email on how to send the faulty unit back to them on my nickel, actually $5.80. I mailed the unit back to them on Monday, March 11 and they received it on Wednesday, March 13. On Tuesday, March 19 I received an email that the original was being replaced and shipped. It arrived back here on Thursday, March 21. Upon opening the replacement package and inspecting the replacement eLogger V4, I noticed that it had the shrink wrap around the pins slit along both sides and folded back over the non-label side of the unit. The leads from the first unit, with my Anderson Power Poles, had been removed and returned. The the original throttle cable, USB connector and original CD-Rom were returned. There was a new CD-Rom in the package as well. It had a note on the sleeve that read, "Please use this version (if not already)". I was already using the software version 10.44. Since I had had so much trouble with the original unit, I very slowly and methodically tested and calibrated this unit. The voltage was carefully calibrated using a Radio Shack Digital Multimeter Cat. No. 22-168A. The unit also needed a re-zeroing of the amps following the directions in the manual. It took many full days, between March 21 and April 2, and at least one reset to factory calibration, before I was satisfied with the calibration and repeatable accuracy of the unit. Even now the voltage is not as accurate as I would like it to be over a typical voltage use range. Compared to the multimeter:

eLogger reads 7.51V

The voltages shown are with no load on the eLogger V4. Only the battery was plugged in for the 'resting' voltage readings. This was as close as I could get the eLogger V4 calibrated to the multimeter. Finally the Emeter 2 with RDU, eLogger V4 unit 2 and Ice 50 were set up to gather Drive Calculator values for the O.S. Motor OMA-5010-810 using a 4S "A123" 2300mAh pack. There were two no load values gathered. One of the no load values was recorded before the load data captures and the other after the load data captures. Four props provided the varying loads. They were all APC props; 10x7E, 11x8.5E, 12x10E and 13x10E. Data was recorded for approximately 10 seconds for each of the no load and loaded data gathering sessions. The data was gathered at an elevation of approximately 287m AMSL and 14.5 degrees C. The Emeter 2, eLogger V4, and CC Ice 50 were all set to capture data twice a second. The recorded data was input into a spreadsheet and collated. The spreadsheet data was used for comparison purposes and to create Drive Calculator motor files. Except for the amps gathered during the no load data gathering, the volts, amps and RPM differences between the Emeter 2 and eLogger V4 were less than 1%. There was a difference of about 4% between the Emeter 2 data and eLogger V4 for the no load amps. Compared to the differences between the Emeter 2 and CC Ice 50, that's not too bad. The difference in volts recorded between the Emeter 2 and CC Ice 50 units was as much as 6% different at 41 amps. The amp difference was up to 76% different at no load (yes, you read that correctly), but the RPM varied only about 1% from the Emeter 2 in all voltage and amp ranges. Two 'motors' each were created in Drive Calculator for all three logging devices. One 'motor' used the averaged data collected during the 10 second run, while the other 'motor' used the median data collected. Drive Calculator uses a slider at the lower right of the main screen to indicate the motor calculation reliability. Drive Calculator also recommends a difference of 3% or less for the best Computed values shown at the bottom left of the main screen.

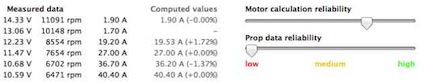

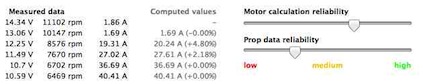

Emeter 2 Average - above Emeter 2 Median -below

The Emeter 2 Average motor shows a +4.80% difference at 12.25V and its Motor calculation reliability is slightly less than that of the Emeter 2 Median data motor, as seen in the screen captures. The motor window for the Emeter 2 Median data shows a calculated Kv of 781.9. In the review of the motor in the March 2013 Ampeer, I had noted that Drive Calculator had calculated a Kv of 790.2.

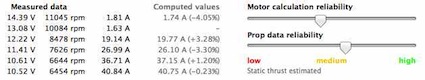

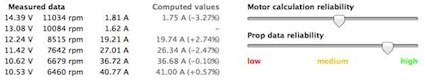

eLogger V4 unit 2 Average

Neither the Average nor Median data for the eLogger V4 unit 2 provided a less than 3% difference in the Computed values, but the Average data came close and had the better Motor calculation reliability. The motor window for the eLogger 2 averaged data showed a calculated Kv of 773.8. The comparison to the Emeter 2 indicates that a reasonably well calibrated eLogger V4 can be used to create useful motor data in Drive Calculator. Next, a really strange thing happened! I expected that the average and median data from the CC Ice 50 would not produce any useful power system prediction data since there is a very large discrepancy in recorded data when the Ice 50 data is compared to the Emeter 2 data. I expected the data to have many Computed values well above a 3% difference.

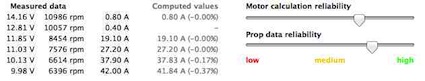

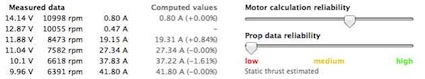

Ice 50 Average

The Computed values and Motor calculation reliability looked surprisingly good for both the average and median data. The median data motor had just a slightly higher Motor calculation reliability. The motor window for the CC Ice 50 median data shows a calculated Kv of 778.7. Some final thoughts: The eLogger V4, once calibrated, has the ability to collect useful data for Drive Calculator input. The price is reasonable. Its relatively small size and measured weight of 30g/1.06 oz. with four Anderson Power Poles installed is easily carried aloft by many electric planes. I didn't like the fact that the first unit didn't work correctly, but that can happen to anything. I also didn't like how easily the pins for the RPM sensor and LDC Expander bend, even when being extremely careful. The shrink wrap around the pins is a 'bother'. Both situations could be corrected by putting a light 'plastic' sleeve around the pins and then shrink wrapping the whole unit. The wire on the LCD is extremely stiff. The stiff wire makes it hard to lay the unit flat on a surface in a given orientation. The brushless RPM sensor manual states to hook up the two wires on the brushless RPM sensor to any two of the motor's three leads. After reading through all of the hook-up information in the brushless RPM sensor instructions, there is some conflicting information when it states that just one wire can be utilized. If the wire input and output leads were on opposite ends of the eLogger, it would be a bit more convenient to hook up in a plane. I'll be using the eLogger V4 for some inflight data gathering this summer. Some additional thoughts: On April 4, I ordered a new Emeter 2 from RC Dude. I had accidentally dropped my Emeter 2 onto the cement basement floor during the winter and the LCD screen developed 'blotches'. It still works well, but the blotches are annoying. The second Emeter 2 was ordered because I do not want to be without this valuable tool. To be fair, and show that an oops can happen to anyone, the new Emeter 2 arrived with a dead battery which I replaced. Upcoming Keith Shaw Birthday Party Electric Fly-in 2013 The Balsa Butchers will once again be hosting the "Keith Shaw Birthday Party Electric Fly-In" at their field near Coldwater, MI. The event will take place on June 8 and 9, 2013. Contest Director: Dave Grife - E-mail: grifesd@yahoo.com or Phone: 517.279.8445

The Flying Field will be open Friday, June 7 for early arrivals Saturday, June 8, hours are from 9 a.m. 'til 5 p.m.

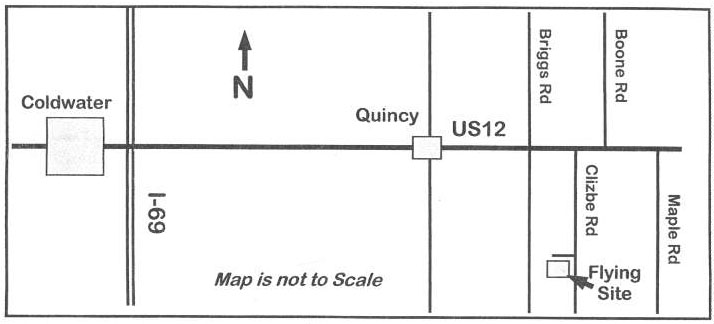

Landing Fee is $10 for the weekend. Directions: Quincy is approximately 4.5 miles east of I-69. Clizbe Road is approximately 1.6 miles east of Quincy. The Flying site is approximately 1.5 miles south of US-12 on the west side of Clizbe Road.

From Pete Foss via email I'd like to announce the date of the Skymasters Electric fly as June 15th with carryover on the 16th. Like last year, we have made arrangements with the DNR to allow overnight rustic camping at the field ($13) to facilitate NIGHT FLYING! Fliers can also stay and open fly on Sunday with the club. Hope to see lots of you there. Saturday, June 15, 2013 Skymasters' Field Event Flying Starts at 10 a.m. and goes until??? Potluck Dinner at the field, bonfire & NIGHT FLYING Camp overnight at the field. Open flying on Sunday. No Landing FEE!!! Lots of parking Refreshments available at the event Pilots' Prizes 94dBa 10 a.m. to 8 p.m. Night Fliers must be EXTRA quiet Field is located in the Bald Mountain Recreation Area About 5 Miles north of the Palace of Auburn Hills on Scripps Rd. between Lapeer Rd. (M24) and Joslyn Rd. Vehicles require Recreation Passport For more info email Pete Foss Pete Foss - Skymasters RC of Michigan More on "Can the Data From the Castle Creations' Phoenix ICE 50 (8S) Be Used to Collect Inputs for Drive Calculator?"

I presented the original article in the June 2012 Ampeer. I'd spent weeks gathering data comparing the ICE 50 data to that obtained by the Emeter 2 and a Radio Shack Digital Multimeter Cat. No. 22-168A and reached the conclusion that the data recorded by the ICE 50 couldn't be used in Drive Calculator to create a useful motor prediction simulation.

The following are the predictions by Drive Calculator for the OMA-5010-810 at 14.8v using an APC 12x8E prop at 287m AMSL and 20-deg C;

Another indication that the CC Ice 50 data is not useful as input into Drive Calculator is the calculated Rd. Rd is Drive Calculator's calculation of the dynamic resistance of all of the components of the power system. Drive Calculator's Rd is not a constant and varies slightly with the applied voltage, so the following Rd numbers are based on 14.8 volts.

While the Ice 50 data is somewhat useful to verify whether power system components might be loaded too heavily, the recorded data does not make a useful motor model for the Drive Calculator power system simulation. Announcing the 29th Annual Mid-America Electric Flies Here are the links to the 2013 Flyer as well as the field map and local area hotels list. 2013 Map to the flying field and local hotels listing To Reach Ken Myers, you can land mail to the address at the top of the page. My E-mail address is: KMyersEFO@theampeer.org |