|

Important: At this time, Mid-February 2012, this article is being updated frequently. If you have questions or corrections you can contact me at kmyersefo@theampeer.org

Return or Go To the Electric Flyers Only of Southeastern Michigan (EFO) Homepage By Ken Myers Originated on December 04, 2007 Last Update: April 24, 2010 Introduction

Example 1: Real World Application - Dymond RC Flite 40

Watts In (power in), Watts Out (power out) and Efficiency Wing Cube Loading (WCL) Factor (formerly referred to as Cubic Wing Loading (CWL)): An Explanation - updated: Jan. 2014 A Performance Factor Typrical Onboard Radio System (ORS) Components K2 Energy 26650 cells - another lithium iron phosphate cell How I Have Been Zip Charging a 3S1P ANR26650M1 (2300mAh) A123 System, Inc. Pack HXT 42-60/06 Motor Review - now known as the Turnigy TR 42-60C Lithium Face Off: A Head-to-Head Comparison of Li-Po, M1/A123 & Emoli - also includes the effects of ambient temperature on these cells Timing Test - demonstrates the effects of different timings on power system output TowerPro 3520-6 #1 Motor Review - This is part of the review for the Sportsman Aviation Sport Stik 40 ARF Low Wing Review on RC Groups. TowerPro 3520-6 #1 (second review) Motor Review - this is the second review of the same motor now being used in the Sports Aviation Ryan STA 40 ARF TowerPro 3520-6 #2 part of the reivew of the Sportsman Aviation Sonic 500 25-46 ARF on RC Groups. Also contains a review of the Jeti Spin 44 ESC and Spinbox programmer. TowerPro 3520-7 Motor Review All motors and cell chemistries can be used in a myriad of ways to power model aircraft. No one way is more correct than another, as long as it works as desired in the application!

By Ken Myers February 2008 There are standards in Lithium based cylindrical cell sizing that are important to know about. There are many different Lithium based rechargeable (secondary) chemistries used in cylindrical cells.

I have personally used the ANR26650M1 cells produced for A123 Systems, Inc. for about eighteen months. Besides my personal experience, I owe a HUGE thanks to Charles of Haralson County, GA who is known as everydayflyer on RC Groups. He got me interested in these cells and has been a great contributor to the knowledge base about these cells on RC Groups.

A123 Systems Inc.

and A123 Racing (appears to be a division of the above)

APR18650M1 (1100mAh)

ANR26650M1; A123 cells, M1 cells, DEWALT 36V cells [DC9360 10-cell], DEWALT 28V [DC9280 8-cell], DEWALT Lithium cells APR18650M1; Black & Decker VPX, VPX cells, smaller A123's, DEWALT 18V [DC9180 6S2P APR18650 cells] Summarized, paraphrased and annotated from: www.a123racing.com/SpecSheets/A123FAQ.pdf This information applies specifically to the ANR26650M1 2300mAh cells but can be generalized to the APR18650M1 1100mAh cells. 1.) The cell is cylindrical in an aluminum canister. It has a nominal voltage of 3.3V and a charge voltage of 3.6V. It has a capacity of 2300mAh, and is capable of 30C (69A) continuous discharges and 60C (138A) pulse (10 second) discharges. Each cell weighs 70 grams (2.47 oz). (See specific notes about the APR18650M1) 2.) A special electronic speed controller (ESC) is not needed to run these batteries. The low voltage cutoff should be set to 2.0V per cell or it can be turned off. (KM Note: It is best to fly timed flights with these cells. There is no knee to warn of lowering power. It's a "cliff" and it drops off "right now!") 3.) There are no special instructions for protection during use or charging. Treat it as you would any other battery. 4.) Balancing is an important precaution when using Lithium batteries. Batteries made up of these cells are not as prone to as much individual cell voltage variance as other batteries, but balancing keeps the pack in good health and ensures maximum cycles. 5.) Voltage sag is how much the voltage drops during the course of a discharge. A Nickel Metal battery's voltage sags throughout the complete discharge. A Nickel Metal battery is only operating at full performance for part of the discharge. The batteries being produced by A123 Systems, Inc. show very little voltage sag during the discharge. (KM Note: until the "bottom drops out" at the end) 6.) These batteries have the fastest charge time for any RC battery. They can be charged to full capacity in 15 minutes or less with a charger capable of providing the input amperage and voltage. Charging at these high rates seems to have no effect on the cycle life of the pack. 7.) These batteries are very safe, and abuse tolerant. They have many safety advantages over Lithium Polymer batteries.

8.) These batteries can be stored at any state of charge for short periods of time 3-5 days. They can also be stored safely for long periods of time. At a 50% to 100% state of charge, the batteries can be stored for 6 months. They can be stored for up to 24 months if they are charged to 100% state of charge beforehand. 9.) Up to 1000 cycles can be expected before reaching 75% capacity. In an average RC application, expect to see over 300 cycles before noticing any change in the battery pack. (KM Note: This has been independently confirmed by several individuals.) 10.) The battery can be charged immediately after use. I am extremely pleased with the safety, performance, ease of care and charging, fast field charging time and longevity of the ANR26650M1 (2300mAh) cells, previously manufactured by China BAK for A123 Systems, Inc. It appears that Enerland Co., Ltd., which is now a division of A123 Systems, Inc., is now the manufacturer.

Ken with Son of Swallow Keith Shaw is using about 150 watts in per cell for his Crosby CR-4 racer.

Keith Shaw's Crosby Racer At the other end of the scale, I have used as little as 25 watts in per cell in my EasyStar RTF with a 2S "A123" pack.

The cells are available from many sources.

Updated July 28, 2008 For a while the prices on individual cells was approaching what the cells were "costing" in DEWALT DC9360 packs on ebay. It appears that the supply of DEWALT DC9360 packs is drying up on ebay, and they are now pretty much in the $160 to $170 range with shipping. Meanwhile, A123 Racing, the supplier of the cells to our suppliers has threatened our suppliers with a notice to cut off their supply if they do not use MAP (manufacturer's advertised pricing). In other words, price fixing is in affect on these cells. It is NOT our suppliers' fault! As I've noted, by December 2008, the DEWALT 9360 10-cell packs on ebay are once again in the $100 range for delivered packs. Sometimes the best deal involves purchasing two packs at once. Sources for individual cells and packs are listed below. |

| Pricing as of January 03, 2008 | |||

| Cell mAh | Link | Price per cell US$ | Notes: |

| 1100 | http://www.robotmarketplace.com/products/battery_build_li-ion.html | $11.00 | Individual cell price In the dropdown menu select 1100mAh A123 |

| 1100 | http://www.battlepack.com/A123.asp | $11.00 | Individual cell price |

| 1100 | http://www.radicalrc.com/shop/?shop=1&cart=1860515&cat=199& | $13.00 | Individual cell price |

| 1100 | http://aircraft-world.com/shopexd.asp?id=5230 | $14.95 | Individual cell price |

| 1100 | http://www.hobbycity.com/hobbycity/store/uh_viewItem.asp?idProduct=6563 | $13.50 | Individual cell price |

| 1100 | http://www.robotmarketplace.com/products/battery_build_li-ion.html | ~$13.50 | Price per cell in packs with connectors |

| 1100 | www.tanicpacks.com/index.php?cPath=111_120_159&osCsid=4b3e05206997b0337da5f284dad62aed | $12.49 - $14.98 | Price per cell in packs w/balance taps Search for 1100mAh 2S thru 4S only |

| 1100 | http://www.walmart.com/catalog/product.do?product_id=7081184 | $9.94 | These were the 2-cell Black & Decker VPX packs They need to be taken apart to get the cells. Packs must be made with leads and taps added. They are no longer available. |

| 2300 | http://www.battlepack.com/A123.asp | $14.50 | Individual cell price voltage enhanced cells also availabe at the same price |

| 2300 | http://www.robotmarketplace.com/products/battery_build_li-ion.html | $16.50 | Individual cell price select 2300mAh A123 in dropdown menu |

| 2300 | http://www.radicalrc.com/shop/?shop=1&cart=1860515&cat=199& | $16.50 | Individual cell price |

| 2300 | http://www.modelelectronicscorp.com/view_products.php?tid=2&stid=5 | $17.00? | Individual cell price Appear to be unavailable as loose cells |

| 2300 | https://www.tanicpacks.com/product_info.php?products_id=932&osCsid=51c8832d962a58a1384e13b36c0cc51f | ~25.00+ | When sold in packs |

| 2300 | http://aircraft-world.com/shopexd.asp?id=5041 | $19.95 | Individual cell price |

| 2300 | http://www.hobbycity.com/hobbycity/store/uh_viewItem.asp?idProduct=6444 | $17.96 | Individual cell price |

| 2300 | http://www.cheapbatterypacks.com/main.asp?sid=1062015&pgid=showlipos&man=A123&cat=A123#AR18650-2S1PF | ~$23.00 | Only sold in Packs from A123 Racing |

| 2300 | http://www.horizonhobby.com/Products/Default.aspx?ProdID=AQR400140 | $19.95 | Individual cell price |

| 2300 | http://www.maxamps.com/products.php?cat=62 | $26.00 | Individual cell price if purchased as 4 cell Developer's kit ~$22.50 per cell in packs |

| 2300 | http://www.robotmarketplace.com/products/battery_build_li-ion.html | ~$19.00 | Price per cell in packs |

| 2300 | http://www.modelelectronicscorp.com/view_products.php?tid=1&stid=2 | $16.50 - $17.50 | In solderless power tubes, no taps |

| 2300 | www.tanicpacks.com/index.php?cPath=111_120&osCsid=fe35bac3c8f038d277c0c8e383329d89 | $22.00 - $26.98 | Pack prices w/taps. Search for A123. |

| 2300 | http://www.horizonhobby.com | $28.35 - $28.50 | Pack prices w/taps. Search for A123. 2-cell & 3-cell packs only. |

| 2300 | http://www.maxamps.com/products.php?cat=62 | $26.25 - $30.00 | Pack prices w/taps. |

| 2300 | http://www.cheapbatterypacks.com/main.asp?sid=1062015&pgid=showlipos&man=A123&cat=A123#AR18650-3S1PT | $25.00 | Pack prices w/taps. Only Available in packs from A123 Racing |

| DEWALT DC9360 10-cell Packs | |||

| 2300 | http://www.ebay.com | $10.13 | Dec. 20, 2008 shipped Reflects best price shipped for two 10-cell packs. |

| 2300 | http://www.pricegrabber.com | $13.40 | Dec. 21, 2008 shipped. |

| 2300 | http://www.amazon.com | $10.60 | December 21, 2008 shipped. |

|

The cells from A123 Racing are said to have a termination voltage of 3.6v or 3.7v and need to be charged to that termination voltage. After a lot of use, I personally prefer 3.85v as the termination voltage. If you already have a NiCad/NiMH or Li-Po charger, Sid Kaufman has an adapter to be used with those types of chargers for charging these cells. He calls it the "Dapter". To find out if your charger will work with the "Dapter", visit this page - Newly Improved! Dapter (a.k.a. LiPoDapter+). A similar device is marketed by Dan Baldwin and is called the Charge Terminator II. I have recently purchased one and have been using it, and I am pleased with its operation and results. If you do not already have a charger, I highly recommend the FMAdirect CellPro 10S or the Tejera Microsystems Engineering, Inc./TME Xtrema. The Xtrema charger also has the capability to be an in-line power meter/watt meter. I have found the Thunder Power TP-1010C to be unacceptable. While it may be an excellent charger for Li-Poly packs, IÕve found it difficult for the average user to use with ÒA123Ó 2300mAh cells and their customer support for these types of cells is nonexistent. Both the CellPro 10S and Xtrema chargers can charge up to 10-cell packs from a 12v DC source like a Marine/RV deep cycle battery or power supply. If you have an AstroFlight 109 Li-Po charger, you may purchase a new chip from Astro Flight. It is called the 555 Software chip for A123 Lithium Ion Charger. Replacing the original Li-Po chip with the new chip modifies the charger for ANR26650M1 (2300mAh) and APR18650M1 (1100mAh) cell use only. If you wish to be able to charge both Li-Po and these types of cells with your AF 109 then you can use this thread to modify your AF 109 - AF109 hardware hack to charge A123 cells by Pat Mackenzie. IMPORTANT NOTE! The following methods are only for those who know what they are doing. Misuse can result in personal and property damage! These cells may also be charged using a power supply such as the MASTECH HY3010E, the MASTECH HY3020E for up to 7 cells or MASTECH HY5020E for up to 17 cells.

For cell combinations where the pack can be broken into three cells groups for charging (i.e. 3, 6, 9, 12 etc.), a Marine/RV deep cycle battery or two in parallel, to increase the capacity NOT the voltage, may be used to directly charge the 3-cell pack(s) from the Marine/RV deep cycle. A How-To for a 3S pack may be found here. If you understand this set up, then even greater numbers of these "3-cell" packs can be done.

One of the big advantages of these cells is that they are very robust and seem to withstand over-charging and over-discharging quite well. They do not seem to need to be balanced with every charge like Li-Po packs. The individual cells do need to be monitored and have balancing leads on them to balance the pack(s) on occasion using the Astro Flight "Blinky" Battery Balancer for A123 Cells. Here is a thread on RC Groups about balancing these packs - Yet another A123 Thread / Balancing, is it necessary? As mentioned before, everydayflyer is an excellent resource for information about these cells. Here is a post that contains links to just about everything you might want to know about these cells. David Theunissen, of the UK, has more useful information here. Recommended background reading on the lithium iron phosphate battery (LiFePO4) for the type these cells belong in. Quoted and paraphrased from the above source: 1.) LiFePO4 was developed by John Goodenough's research group at the University of Texas in 1997. 2.) In 2002, Yet-Ming Chiang and his coworkers at MIT (Massachusetts Institute of Technology) reported that they had successfully doped the cathode with appropriate cations1 - such as aluminum, niobium, and zirconium allowing development to move forward. Products using the doped nanophosphate materials developed by Prof. Chiang are now in high volume mass production by A123Systems and are in use in industrial volumes by major corporations including Black and Decker, DeWALT, General Motors, Daimler, Cessna and BAE Systems among others. 1. Cations (cat-eye-ons) are positively charged ions. Cations have fewer electrons than protons. There has been ongoing litigation between the University of Texas, MIT and A123 Systems, Inc. about patent issues regarding these cells. Rick Page of Victoria, BC Canada posted some interesting information on RC Groups. "A123 says they are producing batteries at their own plants now, but because of the continuing legal actions they are not being more specific. BAK indicated that they may use their A123 tooling with Phostech electrodes to make an A123 substitute but only time will tell. All of which should be very worrisome for A123 investors. The industry seems to have decided that their patent may be invalid. The reason for the A123 high current advantage that was stated in the patent has now turned out to be incorrect and their patent may infringe on the one originally issued to U of Texas and now held by Phostech. Rick." "This is some of what BAK disclosed for their reasons to terminate their contract with A123. BAK is 'the Company'. Quote:

Rick" Also: On February 6, 2008, I was made aware that A123 Systems, Inc. had purchased Enerland Co., Ltd of Korea. Enerland, the manufacturer of extremely high quality Li-Po cells used in Polyquest batteries, FlightPower EVO batteries and more, is now a division of A123 Systems, Inc. and is sharing marketing with the A123 Racing division. My research on the Internet showed that the acquisition was completed in August of 2007. This most likely explains who has been manufacturing the cells since China BAK backed out their deal with A123 Systems, Inc.

What this all means to us, I am not sure at this time. It seems that the DeWALT packs have been increasing in price on ebay, which may indicate that the supply is getting shorter or that the manufacturing costs have risen. What is actually happening at this time is unknown. March 16 - GE buys into A123 Systems, Inc.

CHRIS MORRISON | MARCH 5TH, 2008 In two connected investments, General Electric has put $4 million into Think, a Norwegian electric car manufacturer, and $20 million into A123 Systems, which manufactures batteries that are used in the cars. Both companies are already well funded. Think has taken over $80 million to date and A123 has topped $150 million (past coverage here). The new investment by GE makes it the single largest shareholder in the latter company. On August 8, 2008 A123 Systems, Inc. published their IPO. Think is preparing to roll out the Think City in Europe. 1.) Duration: Flight times for the 2300mAh cells are good at about 100 watts in per cell static. They usually provide about 7 minutes of fully aerobatic flight. That is slightly better than a 25C 2600mAh Li-Po, which should only be run to about 80% of its capacity, giving it a usable capacity of about 2100mAh. Unfortunately the weight penality is noted below. 2.) Weight: A 6-cell pack made up of ANR26650M1 2300mAh cells weighs a bit over 17 oz. with wiring and connectors. A 6-cell 2600mAh 25C Li-Po (equivalent voltage to a 6-cell pack made up of ANR26650M1 2300mAh cells) weighs about 12.25 oz. The Li-Po weight is based on 5S1P Thunder Power eXtremeV2 cells. A 6-cell "A123" pack can be made from a DEWALT DC9360 for about $100 including wire, connectors and node/balance connector. A Thunder Power 5S eXtremeV2 pack can be purchased for about $150 without power lead connectors. 3.) Form factor: There are times when it is much easier to get the low-profile brick-type form factor of a Li-Po pack to fit well into a given plane. 4.) Easy Availability of Li-Po packs: The availability of pre-made Li-Po packs, to power our electrically powered models, is extremely high with many mAh capacities, power ratings and physical form factor choices. They come ready to use. 5.) Ease of charging: With the very large number of Li-Po packs being sold, finding a charger is much easier for Li-Po cells, as well as Nickel type packs. 6.) Ease of motor selection: A majority of power systems, recommended for today's aircraft, are based on Li-Po use and require some serious rethinking when using the cells from A123 Systems, Inc. 7.) Cell voltage difference: Because the single cell voltage of LiFePO4 is quite different from Nickel based cells and Li-Po cells, direct conversion in existing systems is sometimes difficult. Using 100 watts in per cell makes figuring the completed, ready to fly (RTF) target weight very easy. A two pound (32 oz./900g) plane, 2 cells, a three pound (48 oz./1350g) plane 3 cells, etc.

Table 1 shows the anticipated battery weight including balance leads and plugs, power leads and connectors, shrink-wrap or equivalent tape and Velcro for two-cell through ten-cell packs of ANR26650M1 2300mAh cells. It is not really necessary to know the weight of the pack when selecting the appropriate power system components (motor/prop/ESC) and airframe, but the table gives a realistic idea of how much these cells weigh when configured into packs. A single ANR26650M1 2300mAh cell has a diameter of 1.045 inches (26.5mm) and length of 2.6 inches (66mm). In the USA, pieces of 1-inch diameter wooden dowel rod can be cut to the appropiate length and then taped together to form a dummy pack to try different cell configurations in a given project to see what pack configuration will fit best into the desired location in the plane. The Maximum Completed Airframe (MCA) weight is the key element when selecting an appropriate power system. Tables 2 and 2a show MCA weights and suggested wing area ranges for two through ten cell packs to be used for sport and sport scale planes. As always, there are a lot of exceptions, but in general, these numbers work relatively well for prop driven sport and sport scale aircraft. The Maximum Completed Airframe (MCA) weight includes everything that is not part of the onboard radio system and its installation weights and the motor and battery components and their installation weights. The suggested wing area range is based on typical Wing Cube Loading (WCL) Factors for these types of aircraft. Both somewhat larger and smaller wing areas may also be used successfully. The MCA weight, with its resulting RTF target weight, is the primary determinate in selecting the most appropriate number of cells with the wing area being a secondary consideration. If you already have an Almost Ready to Fly (ARF) model kit, it is quite easy to determine the MCA weight and the resulting RTF target weight. Weigh all of the parts that make up the airframe including the landing gear and wheels to be used. Add the parts' weights and you have a number close enough to use for the MCA weight. If you already have a builder's kit onhand, weigh all of the parts for the airframe, the plans and don't forget the landing gear (main, nose or tail) and wheels to be used. Add them together, and it should yield a reasonably close MCA weight. When doing a glow conversion, if you don't have the airframe at hand, a best guess estimate for the MCA weight would be about 60% of the highest advertised weight. If you can find a review of the plane, the weights of the actual components the reviewer used could be subtracted from the total weight to give an approximate MCA weight. Another way to estimate what the RTF target weight of a glow conversion, without using the MCA weight, might be is to increase the highest advertised weight by 15%. To do that, multiply the highest advertised RTF weight by 1.176. Use that as the RTF target weight for figuring the number of cells. The MAC weight then becomes unnecessary, but can be estimated at 1/2 the RTF target weight. There are not a lot of sport and sport scale planes designed for electric power systems. Many of those that are available are also designed for 3D aerobatics. These tend to be quite light in structure. Since Li-Po cells are usually recommended for these planes, increase the highest advertised weight by 10% (multiply by 1.111) to derive a RTF target weight for selecting the number of ANR26650M1 2300mAh cells. Many manufactures and suppilers provide the wing area, but then again, many don't. Some who do supply this information don't get it right. When the plane is available, measure and compute the wing area. If the plane is not physically present, you'll have to rely on manufacturer/supplier data. A quick look at Table 2 shows that the MCA weight is approximately 1/2 the RTF target weight. Simply double the MCA weight for the approximate RTF target weight. Use the approximate RTF target weight, in pounds, as a guide for the selecting the number of ANR26650M1 2300mAh cells to use for the project. Round up the number of required cells when the RTF target weight, in pounds, includes a decimal greater than .45. I have found that, on average, for these types of planes, the onboard radio system weight is about 12.5% of the RTF target weight. The ORS weight may include the radio receiver, switch harness, Electronic Speed Control (ESC) with or without a Battery Eliminator Circuit (BEC), servos, servo extensions, push rods, control horns, plywood used to mount the servos, onboard receiver battery or switching BEC for planes with a cell count over 3, or any parts of the radio control system. It is not necessary to know the Onboard Radio System (ORS) weight for selecting a power system, but here is a table that gives an idea of the ORS weight for reference. The actual ORS parts used depend on the individual plane. Here are some typical examples for ORS components. Sometimes, as is the case with many ARF type planes, the servo mounting plywood will be installed in the airframe. It does not make much of a difference when determining the MCA weight and resulting RTF target weight. The first step in selecting an appropriate motor and prop combination is to figure out what props match the airframe and its mission, in this case, sport and sport scale non-3D aerobatic flying. There are many props available from various manufacturers and suppliers. Again, to keep it simple, I use only APC props. I do not use the SF (slow fly) or Pylon props as they are inappropriate for this type of flying. APC props may or may not be the best for a particular application, but they are readily available and work well in most cases. For Sport and Sport Scale planes I recommend a prop disk loading (PDL) of between 75 oz./sq.ft. of prop disk area and 120 oz./sq.ft. of prop disk area. To simplify this process I have a created a table of prop diameter sizes for each ANR26650M1 2300mAh cell count. Recommended prop diameter table Larger prop diameters are more efficient. Sometimes it is necessary to limit the prop diameter because of landing gear considerations. Whenever possible, use the largest prop diameter the airframe can accommodate with a pitch and RPM combination that will allow at least the minimum recommended pitch speed to be reached. In general, typical sport/sport scale planes have a pitch speed ((RPM * pitch in inches)/1056) between 50 mph (80.5km/hr) and 70 mph (112.5km/hr). Using the stall speed and 3.5 times the stall speed, I have created tables that show possible APC props and the minimum required RPM for the appropriate pitch speed for each ANR26650M1 2300mAh cell count and matching airframe combination.

2 cell table

The manufacturers and suppliers do a terrible job at helping us to select an appropriate, suitable motor. Table 3 shows what I believe to be the appropriate "typical" weight range for brushless outrunner motors for sport and sport scale planes. It provides a starting point for selecting a motor for a given sport or sport scale project. The Weight Table was calculated using 1.5 watts in (in the process of changing this to 1.75 watts per gram - Jan. '09) (the heaviest motor in a group) for each gram of motor weight and 3.0 watts in (the lightest motor in a group) for each gram of motor weight. I have read reviews where the reviewer has used between 3.5 and up to 4 or more, but for these types of planes, the motor ends up being too light and, it is being "worked too hard." It is not always "best" to use the lightest motor in a group of similar motors. A heavier motor will make balancing the plane easier and it will be "working" easier. The prop adapter, motor mount, prop, mounting hardware, etc. can add another 30% of the motor weight to the total installed motor weight for this type of project. Knowing the appropriate motor weight for the project is the first step in selecting an appropriate brushless outrunner motor. The second step is determining the appropriate motor Kv. I created a method to estimate the approximate appropriate Kv range. Once the motor weight and Kv have been determined, a motor can be selected that may work in the intended application. The process uses many steps to determine the Kv range. Included in the process are; RTF weight Wing Area Stall speed 3.5 times the stall speed Suggested Prop diameter The method uses suggested prop diameters based on prop disk loading and the required pitch speed. The required pitch speed is based on the stall speed to pitch speed ratio to match the pitch. Table 4 shows what I believe to be the appropriate prop diameter and Kv ranges for typical sport/sport scale planes for the number of ANR26650M1 2300mAh cells in the pack. Sometimes a slightly higher Kv or slightly lower Kv than recommended may be used in a specific pack size group. If real world testing shows that a motor is swinging an appropriate prop for a group at the required RPM, then that motor may be used in the group. One specific example is the HXT 42-60/06 (now known as the Turnigy TR 42-60C) in the 5S group, even though the Kv is lower than the recommended Kv for 5S packs. I've also identified a couple of TowerPro motors that also work "outside" the Kv group, because I have the data to make reasonably accurate predictons about their performance. The higher the Kv in a given range, the smaller the diameter the prop will have to be to be pulling only about 35 amps. It also may be necessary to use the next lower set of Kv numbers to get the larger diameter props to only pull about 35 amps, but then the RPM may be below the desired pitch speed. In the following tables, using Drive Calculator, I have suggested possible props that meet the diameter requirement and RPM required for the pitch speed when pulling about 35 amps at sea level and 17-deg C. The vast majority of motors are noted with no usable prop data available (NUPDA). This means that the manufacturer/supplier does not have sufficient data available to make a reasonable "guess" as to what prop might be used with any given number of ANR26650M1 2300mAh cells, or other cells for that matter. Caution: It is best not to choose a motor at either Kv extreme for a given cell count. If you already have one of the motors listed at the extreme, you might consider testing it, but may need a different motor. A motor with a Kv that is too low might require a prop with a diameter that will not work with the landing gear clearance for grass field take offs. A motor with a Kv that is too high might not be able to turn the minimum recommended prop diameter with the required pitch to meet the minimum pitch speed without going way over the 35 amp desired amp draw for this application. For an example of how I would go about selecting a motor for a proposed application, read Example 2 - A Proposed Application. Showing 2-stroke & 4-stroke Glow Equivalents For Comparison 2S Motor Suggestions 3S Motor Suggestions 4S Motor Suggestions 5S Motor Suggestions 6S Motor Suggestions 7S Motor Suggestions 8S Motor Suggestions 9S Motor Suggestions 10S Motor Suggestions By Ken Myers (A Fully Detailed Review can be found on the RC Groups thread: www.rcgroups.com/forums/showthread.php?t=735972 KM)

Step 1: Determine the MAC weight - All of the ARF kit parts that might be used in the conversion weighed a total of 1295.2g or 45.69 oz.

I originally flew this plane with a TowerPro 3520-7 using an APC 12x7 sport prop and a 6S ANR26650M1 2300mAh pack. It was okay, but that motor is really "best" used with a 5S ANR26650M1 2300mAh pack. I wanted to go with a larger diameter prop for better prop efficiency. I didn't want to spend much. I chose the HXT 42-60/06 (now known as the Turnigy TR 42-60C) because it was the cheapest and I wanted to know if it was "adequate". It worked okay and allowed me to compare it to my AXI 4120/18, which I run wiith a 6S ANR26650M1 2300mAh pack in my Fusion sport plane. By Ken Myers - 11/24/07

The proposed model, by design, has 416.5 sq.in. of wing area and will be about 3 pounds or less, making it suitable for a 3S ANR26650M1 2300mAh pack. Since it is being specifically designed to use a 3S pack, it has ground clearance to use an 11-inch diameter prop. It will have a WCL factor of 9.75 or less.

The same process is used. Using the table, determine 10-inch prop appropitate motors by their Kv numbers including any NUPDA noted motors that fall within the Kv range.

If and when this plane gets off the drawing board, what am I really going to use? I already have a Hyperion Z3019-10 that is sitting in a drawer, therefore, I am creating this plane to use that motor. Ideally, I would use the Scorpion S3020-12, if I were purchasing a new motor for the project.

By the end of December 2007 I had run across a plane by Fred Reese called the Swallow. I liked its looks and decided to redesign it to the specifications I had noted above for the Basic 3S Sport Plane. I used my "drawered" Hyperion Z3019-10 for the motor, so I was limited to a 10" prop diameter to keep the static current in the 35 amp area. The Finished SOS for comparison to the Basic 3S Sport Plane from above Wing area: ~415 sq.in.

The Son of Swallow took to the air in April and has proved to be everything that I "predicted" it to be. To learn more about the SOS, its design and flight characteristics, visit this thread on RC Groups.

I have gathered a lot of information about typical electrically powered sport and sport scale planes and have found the average WCL factor for sport/sport scale planes to be about 8.5 and about 11.5 for Advanced sport/sport scale planes. Those two numbers were used for the recommended wing area ranges in Table 2 and Table 2a.

The following are some examples of typical ORS system components and their measured weights. The components listed are for example only. The builder of the model must determine which components are "correct" for the specific use and will be SAFE to use. DO NOT skimp on servo power!

Watts In (power in), Watts Out (power out) and Efficiency Watts in is easily measured using an in-line power meter such as the Astro Flight Super Whattmeter. An in-line power meter is an ESSENTIAL tool when using electric motors to power model aircraft! The power in, when talking about electricity, is expressed as watts in, which is equal to the volts in times the amps in. Watts in is used by authors when they give motor power specifications. They tend to just use the term watts without signifying that it is watts in.

DC data:

10/17/07 Real World comparision:

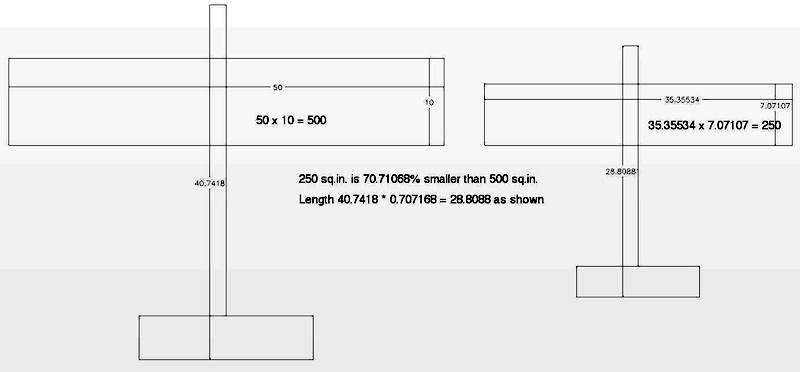

Return to the Appendix Return to Example 1 Formerly referred here to as Cubic Wing Loading (CWL): An Explanation By Ken Myers Updated: January 4, 2014 The Wing Cube Loading (WCL) factor is an indicator used for grouping radio controlled miniature aircraft by their possible flight characteristics. Some people feel that it is a better flyability indicator than wing area loading (WAL) expressed in oz./sq.ft. of wing area. The WCL factor, like WAL, has little to do with the aerodynamics needed to get the model to fly at various sizes/scales in real, un-scaleable air. For me, the WCL factor seems to be easier to understand and more useful than the more commonly used wing loading. The common wing area loading uses the ready to fly (RTF) weight in ounces (oz.) related to the wing area in square feet (sq.ft.). In Imperial units the wing loading is given as ounces per square foot (oz./sq.ft.). Using the wing cube loading (WCL) factor, because it is not 'size' dependent, makes it easier to comprehend the flyability of a plane. If a person states that their aircraft has a WCL factor of 8, no other mental calculations need to be performed, That plane will fly in a similar manner to other aircraft with a WCL factor of about 8. Using wing area loading (WAL) is a two step process to understand how a given plane might fly. If someone says that their model has a 20 oz./sq.ft. wing loading, then the physical size of the model must be taken into consideration. A plane with a 400 sq.in. wing with a 20 oz./sq.ft. wing area loading will fly very differently from one with a 1200 sq.in. wing with the same 20 oz./sq.ft. wing area loading. Both the wing area loading and the wing area must be known by the experienced modeler to determine the possible flight characteristics using the wing area loading method. The WCL factor indicates the relative ease of flying, or skill level, required to fly various RC model aircraft and allows for ability or "flyability" groupings of these aircraft. As previously noted, it appears that when two aircraft, with the same wing loading, are sized or scaled differently, they fly differently. A "giant scale" model of about 1200 sq.in. with a 32 oz./sq.ft. wing loading seems to fly, subjectively, much differently, and seems to the pilot, more easily, than a 400 sq.in. model with the same 32 oz./sq.ft. wing loading. The wing cube loading (WCL) factor attempts to handle this apparent difference in "flyability" using a mathematical model. The model takes the two-dimensional wing area and changes it to a mathematical equivalent volume. The mathematical volume is not related to the "real" volume of the three-dimensional wing. The WCL factor does not take into consideration the actual airfoil or aerodynamics required to get the plane to fly at a given size or scale in "real" air. It simply applies an ease of flight FACTOR for grouping and comparing aircraft by possible flight characteristics. We create useful mathematical models to help us understand many things. Electrically powered model builders and fliers are aware of and use these types of mathematical models a lot. An example would be when trying to determine the power loss through an electrically powered motor system. Factors such as Io, Rm, Kv, amps and volts are put into a mathematical formula/model to give an answer that approximates what the output power might be. Here is an example: If a model's ready to fly (RTF) weight is 60 ounces and it has 500 sq.in. of wing area, the WCL factor = 60 oz. / ((500 sq.in. / 144 sq.in.)^1.5)

When a number is raised to the 3rd power it is called cubing the number, which is the number times the number times the number. But why raise square feet to the 1.5 if we want the number cubed? The example aircraft then has a wing loading of 60 oz. / (500 sq.in. / 144 sq.in.) = 17.28 oz./sq.ft. and a WCL factor of 60 / (500 / 144)^1.5 = 9.27. It has a flyability similar to others with a WCL factor of 9.27, but will only have a similar flyability to planes with between 400 sq.in. and 600 sq.in. wings having a WAL of 17.28 oz./sq.ft. How is using the wing cube loading (WCL) factor, instead of the wing loading in ounces per square foot, useful to us? A similarly designed plane of 250 sq.in. is not half the size of 500 sq.in. used for the example. Actually it is only about 30% smaller. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

For the smaller model, with a 250 sq.in. wing, to have about the same flight characteristics, providing it is designed properly to fly at the reduced scale, it would have to have the same WCL factor of 9.27. It would weigh (250/144)^1.5 * 9.27 = an RTF weight of 21.2 oz. yielding a wing area loading of 11.65 oz./sq.ft. Notice that the wing area loading of this 250 sq.in. model is a much lighter wing loading than the 500 sq.in. winged example, which has a wing area loading of 17.28 oz./sq.ft. Even though the wing loadings are different for the two models, with the appropriate power system and aerodynamics, the 250 sq.in. plane would have much the same "feel" and flight characteristics as the 500 sq.in. model. A 1000 sq.in. example for the same type/task aircraft (about 30% larger), using the same cubic wing loading, yields a RTF weight of (1000 / 144) ^1.5 * 9.27 = 169.64 oz. Its wing loading would be 169.64 / (1000/144) or 24.42 oz./sq.ft. Again, the 1000 sq.in. model would have the same "feel" and flight characteristics as the other two sizes, given the proper power and aerodynamics. I believe that the WCL factor is a valid indicator of flight characteristics, even more so than the traditional wing area loading. The three different size examples of the same plane, using wing area loadings of 11.65 oz./sq.ft., 17.28 oz./sq.ft. and 24.42 oz./sq.ft., all would have pretty much the same "feel" to the pilot and exhibit close to the same flight characteristics, but their wing area loadings are very different, especially if the smallest version with an 11.65 oz./sq.ft. WAL is compared to the biggest at 24.42 oz./sq.ft WAL. In Getting Started In Backyard Flying by Bob Aberle, Bob chose to group model types using weight, wing area and wing loading. When WCL factor is used instead of wing loading in oz./sq.ft., some interesting things come to light. Bob created several groups (p.64, p.65); Ultra Micro, Up to 2 oz., wing area 50-100 sq.in., wing loading up to 5 oz./sq.ft.

While none of these planes would be considered "hard to fly" by an experienced R/C pilot, arranging them by wing area loading first and then by the WCL factor demonstrates why and how the WCL factor can be useful.

If you simply base the relative ease of flying on the wing area loading, then the above arrangement would be from the easiest to fly to the hardest to fly. What is interesting is what happens to this arrangement when the WCL factor is used. Parking Lot & Backyard: Merlin, WCL factor 2.54

If you have experienced flying some of these or similar models, you should be able to see that using the WCL factor gives a more realistic idea about the relative ease of flight of the various models. For many years I have collected data for propeller driven model aircraft using glow, gas and electric power systems. I have archived and analyzed that data in an Excel workbook with several spreadsheets. The Excel workbook is available and may be downloaded to your computer by clicking here. Based on the collected data, I have created the following WCL factor levels. Some planes won't work in a given physical environment, where I've used a physical description, but they fly like others in the level. Not all aircraft will fit the title or level grouping I have given. An example that doesn't fit the physical environment is the SR Batteries Eindecker E1 powered by a Zenoah G-26 gasoline engine. In a review published in Model Aviation it had a given wing area of 1700 sq.in. and RTF weight of 16 lb. 13.5 ounces (269.5 oz) for a wing loading of 22.83 oz./sq.ft. and wing cube loading (WCL) factor of 6.64. Therefore, this plane fits in my group called Level 3 (typically Park Flyers), but you'd not fly it in a park! However, the relative ease of flight is very much like a park flyer!

The levels are purely arbitrary. A plane on the high end of one WCL level will most likely fly in a similar manner to one on the low level of the next higher WCL level. For comparison, several WCL factors were noted in "Aircraft Performance Parameters Revisited" by Roger Jaffe, Model Builder, June 1994. Type of Aircraft Wing Cube Loading Factors

The table also illustrates the trend over the past couple of decades to larger glow and gas powered models. Since the data was mostly collected from modeling magazines, and the magazines reflect the "current trends", there are few reviews of the more "typical" .20-size to .60-size glow planes. There is also a hint, in my collected data, of a Level 0 emerging. I only have data for one plane, but have read about others that might become part of this new level. The Level 0 planes might be called "Living Room" Flyers. More Information on wing cube loading (WCL) Factors

Updated: June 29, 2008 The wing cube loading (WCL) factor is an indicator of the "flyability" of a given model. It does not indicate the type of performance that can be expected. Watts in is a typical indicator of performance. It is a pretty reliable rule of thumb in most cases, when talking about electrically powered planes. I DO recommend it as one indicator of performance, but it is difficult to relate glow and gas powered propeller driven models to electrically powered models using that method. It is also difficult to relate the performance of a model "flying on the wing" to one "flying on the prop."

A performance factor theory: One component of my performance factor theory is the pitch speed to stall speed ratio. It can be equally applied to both glow and gas and electrically powered propeller driven models. The pitch speed (PS) to stall speed (SS) ratio relates the theoretical pitch speed to the theoretical stall speed. Ratio of Pitch speed to Stall speed: In Keith Shaw's ground breaking "Electric Sport Scale" article from the July 1987 Model Builder magazine, he states; "The stall speed of our models depends on the wing loading, airfoil choice and surface contour finish, but fortunately is not a very strong function of any of these. At wing loadings of 14 to 25 oz./sq. ft. and the nominal airfoils used in sport scale, an amazingly reliable stall speed estimate is:

Stall speed (mph) = 3.7 x the sq. root of the wing loading (oz./sq.ft.)

Some specific examples of pitch speed to stall speed ratios: Theoretical Pitch Speed (PS) in mph = (Pitch [in inches] times the prop RPM) divided by 1056

I have owned and flown the SR Batteries Bantam monoplane backyard flyer. My version used all of the recommended components. It has 210 sq.in. of wing area and weighs 8.3 oz. ready to fly, which yields a WCL factor of 4.71. (Level 2). It has a pitch speed of 16.7 mph and stall speed of 8.83 mph and pitch speed to stall speed ratio of ~1.89. According to Keith's statement, this plane would most likely NOT do a nice inside loop from level flight, and it wouldn't. The plane required a dive to do a nice inside loop.  My ElectroFlying Fusion sport plane has a wing area of 569 sq.in. and weighs 73.9 oz. ready to fly. The WCL factor is 9.41, which is towards the high end of Level 4, typical sport. It has a pitch speed of ~74 mph and stall speed of ~16 mph with a pitch speed to stall speed ratio of 4.62. Keith's statement indicates that this plane should have "fighter-type" performance, and it does! If "flying on the wing" were the only type of flying task to be considered, then this performance indicator would be sufficient to make valid comparisons between performances of various propeller driven models.

"... Static thrust is the value (usually in pounds in 'English' unit countries) measured 'on the bench'. The oncoming air-speed is '0'. The number derived from measuring static thrust is a very useful number if you are designing helicopters or '3D' aircraft, but has little bearing on choosing the proper propeller for just about any other model.

Tom's statements indicate that the thrust to weight ratio is not an accurate reflection of the possible performance, but does have some effect on the total flight performance.

My first attempts to create a useful model for a Performance Factor (PF) did not work out very well. My Multiplex EasyStar kept coming out in the middle of the performance range, when it actually has almost the least perceived performance of all of my planes. The problem was that the EasyStar has a high theoretical pitch speed that it can NEVER reach because of its design, approximately 48 mph! The high PS relative to the low stall speed (SS) gave it a high pitch speed to stall speed ratio.

In the February 1994 issue of Model Airplane News, Mitch Poling, in his article "New Thoughts on Gearing" provided the following, "My equation for thrust: (Mitch's not Ken's KM)

At that time, I felt that it didn't do a very good job of predicting the static thrust, because there was a variable in the formula that depended on the type/brand of prop, and of course did not take into account any of the other variables that affect a prop's static thrust. It languished in my memory for the next almost 15 years.

I found that I did need a "form factor" to allow my planes to be aligned more closely to my perceived performance. Actually, my form factor consists of two parts. Part one is the diameter in inches divided by the pitch in inches and part two is multiplying the whole formula by 0.5. I derived the 0.5 after looking at a lot of props and comparing the predicted thrust to the numbers that I was getting using this formula without the 0.5 factor.

Ken Myers' thrust formula, used as part of the total Performance Factor. Thrust (ounces) = Pitch (inches) x Diameter3 (inches) x RPM2 x (Diameter (inches) / Pitch (inches) x l0-10 x 0.5

The thrust to weight ratio is the Thrust in ounces from the above formula divided by the RTF Weight in ounces. My "Original" Total Performance Factor:

Near the first part of June 2008, it became very apparent, while testing some K2 Energy 26650 lithium iron phosphate cells (see K2 Cells) that the pitch speed to stall speed ratio was the dominant part of the equation. I found that by squaring the pitch speed to stall speed ratio, all of my aircraft lined up exactly as I perceive them to perform. My "Latest" Total Performance Factor:

Hangar 9 FuntanaX 100 from my archived data

Photo from Horizon Hobby Web site

What can be learned from the above data? 1. The glow versions might be perceived by the same pilot as slightly "easier" to fly based on the WCL factor. The difference in WCL factor is quite small, so it is also possible that the same pilot would not notice any difference in the "flyability" of the three versions.

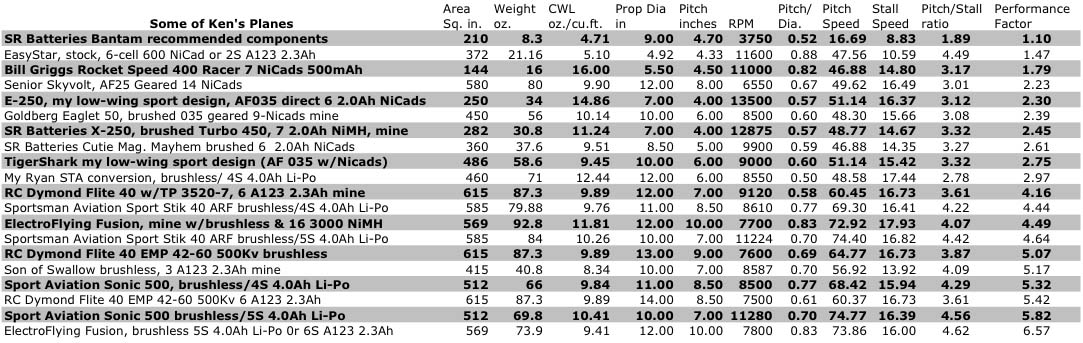

The following shows some of my planes sorted by their performance factors. The sorting is very close to what I believe their perceived performance to be in relationship to each other.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The following reflects the data I've collected to date for the PF levels in the various WCL Factor levels.

All of the data can be down loaded as an Excel spreadsheet at metricnewtheory.xls This section has been moved to its own article. The spinning propeller can be thought of as a circular disk. The area of that circular disk may have a weight loading assigned to it, just as wing area may have a weight loading assigned to it. The prop disk loading (PDL) is expressed in oz./sq.ft of prop disk area. The formula for the area of a circle is Pi*r2. The PDL = RTF weight in ounces/prop disk area in sq.ft.

BEC (Battery Eliminator Circuit): an electronic circuit/power supply that eliminates the need for an onboard NiCad or NiMH battery to power the receiver and servos. The usual type, which is built into an electronic speed control (ESC), is known as a linear BEC. There are also switching, external BECs. For both types, as the applied voltage increases (more cells in the motor battery) the ability of the BEC to supply the correct voltage to the receiver and servos goes down. In general, a linear BEC is limited to 10 volts in and three servos. It is VERY IMPORTANT for the user to follow the ESC manufacturer's recommendation when using built-in BECs! If the BEC part of the ESC "dies", the onboard radio becomes nonfunctional resulting in a crash with possible personal or property damage.

Brushless Outrunner Electric Motor: A type of brushless electric motor that spins its outer bell of magnets around its windings on a fixed stator. As a group, they tend to have a lower Kv (RPM/v) than inrunners. That means that with same applied voltage, outrunners turn more slowly than inrunners and produce more torque. An outrunner is used for directly turning propellers without the extra weight of a gearbox to get the desired torque.

C C is the cell capacity in Ah (amp hours). The ANR26650M1 2300mAh cell is said to have a capacity of 2.3Ah (2300mAh). A discharge rate of 15C means 15 times the C rating of 2.3Ah = 34.5 amps.

ESC (Electronic Speed Control) is the electrical device that allows the motor to vary its RPM. It varies the RPM by switching the motor from full on to full off at a very high rate. When the throttle is "wide open", or off, there is no switching going on. The switches (FETs) remain on all the time at "wide open" throttle and closed at no throttle. At partial throttle, the RPM is being varied by how long the switches are allowed to stay on over time. Since the FETs are a switch, there are only two states for it, on or off. Everytime the switches are in the on state, the motor is trying to draw the same amount of current as the "wide open" throttle position. If an inline power meter is used with the throttle at partial throttle, it appears that the motor is drawing less amps than at full throttle. Because the switching is so fast, the meter cannot display what is actually going on and gives an average power reading in volts, amps and watts. An ESC does NOT act like a water valve which restricts the water flow physically! Early speed controls, for brushed motors, acted somewhat like a water valve. They had a wiper arm on a variable resistor that was moved by a servo, thus restricting the flow of current by increasing the resistance in the circuit. Yep, they could get very hot.

ANR26650M1: A type of lithium iron phosphate secondary cell marketed and manufactured by A123 Systems. It is designated as a 26650 size cell. The charged resting voltage appears to be between 3.6v and 3.7 volts.

Sport Plane: any type of fixed-wing model aircraft that does not resemble a specific full-scale aircraft.

Sport Scale Plane: any type of fixed-wing model aircraft that resembles a specific full-scale aircraft but without all of the details of a true scale model.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||